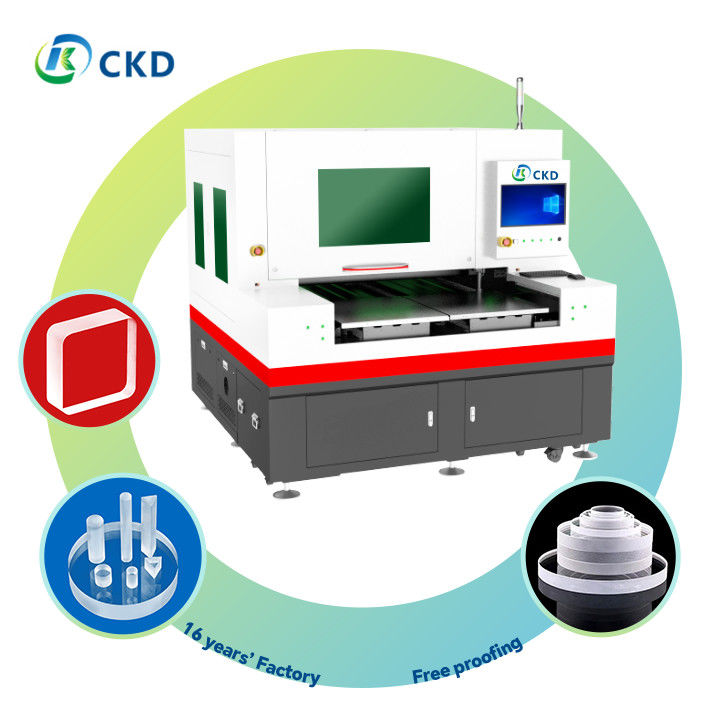

Высокопроизводительная лазерная стеклорезная машина для крупномасштабного производства с точностью ± 0,01 мм

-

Точность позиционирования± 2 мкм

-

Вес3500 кг

-

Ширина резки0.03-25 мм

-

Рабочая среда26°C

-

Разделяющий лазерный источник Тип лазераRFC02 (Радиочастотный CO2)

-

Повторяемость±1,5 мкм

-

Марка линейного руководстваTPI

-

ПреимуществаНеравномерная форма Высокая скорость резки Высокое качество резки, без зазубления, без зазубления, н

-

Частота работы50Hz/60HZ

-

МатериалыСтекло, акрил, пластик, дерево и т.д.

-

Размер резки40*50 см*2

-

Рабочая зона1500 мм х 3000 мм

-

Послепродажное обслуживаниеОнлайн-поддержка, полевое обслуживание и ремонт

-

Мощность лазера1000 Вт

-

Тип лазераЛазерные волокна

-

Точность± 0,01 мм

-

Рабочий столМедоносная палочка/Алюминиевое лезвие

-

Площадь резки400*500*600*700/600*900 мм

-

Коммерческое названиАвтомат для резки стеклянного лазера

-

Система охлажденияОхлаждение водой

-

Скорость резкиДо 1 м/мин

-

Система передачилинейный ведущий брус

-

Место происхожденияКНР

-

Фирменное наименованиеCKD

-

СертификацияISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

ЦенаNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

Высокопроизводительная лазерная стеклорезная машина для крупномасштабного производства с точностью ± 0,01 мм

Описание продукта:

Высокоточная лазерная машина для резки стекла - это современное оборудование, предназначенное для точной и эффективной резки различных типов стекла. Эта передовая машина предлагает широкий спектр настраиваемых опций для удовлетворения конкретных потребностей, включая размер стола, мощность лазера (до 500 Вт) и специальные режущие головки для криволинейной или микроуровневой резки.

Оснащенная передовыми технологиями, эта режущая машина поддерживает различные форматы изображений и текста, такие как AI, PLT, DXF, BMP, Dst, DWg, LAS и DXP, обеспечивая совместимость с различными файлами дизайна для бесперебойной работы.

Благодаря системе управления HTI, эта машина предоставляет удобный интерфейс для удобной навигации и управления, позволяя операторам точно и эффективно настраивать параметры.

Высокоточная лазерная машина для резки стекла предлагает многочисленные преимущества, что делает ее идеальным выбором для применений, требующих резки стекла неправильной формы. Благодаря своим высокоскоростным возможностям резки и превосходному качеству резки, эта машина обеспечивает безупречные результаты без конусности, заусенцев или небольших сколов. Кроме того, она может похвастаться высокой скоростью выхода, низким потреблением расходных материалов и функциями энергосбережения, что делает ее экономически эффективным решением для бизнеса.

Одним из ключевых преимуществ этой машины является ее раздельный лазерный источник RFC02 (радиочастотный CO2), который обеспечивает исключительную производительность для широкого спектра задач резки. Лазерный источник RFC02 работает на частоте 10,6 мкм и обеспечивает выходную мощность 150 Вт, с возможностью выбора 250 Вт и 350 Вт. Его система водяного охлаждения обеспечивает эффективную работу и оптимальную производительность при длительном использовании.

Если вам нужно резать стекло неправильной формы или требуется высокоточная лазерная резка для сложных конструкций, высокоточная лазерная машина для резки стекла - идеальный выбор. Ее универсальность, эффективность и надежность делают ее ценным активом для различных отраслей, включая производство, автомобилестроение, электронику и многое другое.

Особенности:

- Название продукта: Лазерная машина для резки стекла

- Минимальный размер заусенца при резке: ≤5 мкм

- Настраиваемые параметры: Доступны пользовательские параметры для размера стола, мощности лазера (до 500 Вт) и специальных режущих головок (например, для криволинейной или микроуровневой резки) для удовлетворения конкретных потребностей.

- Импульсная частота: 1-100 кГц

- Качество луча: M² < 1.2

- Требования к техническому обслуживанию: Рекомендуется оптическая юстировка каждые 200 часов и замена охлаждающей жидкости каждые 1000 часов. Доступна регулярная удаленная диагностика и обновления программного обеспечения.

Технические параметры:

| Размер рабочей области | 610*700 мм X 2 Настраиваемый |

| Длина волны раздельного лазерного источника | 10,6 мкм |

| Тип лазера | Инфракрасный пикосекундный |

| Применимые материалы | Сверхпрозрачное стекло, обычное белое стекло, высокоборосиликатное стекло, кварцевое стекло, оптическое стекло, покровное стекло, стекло для камер, и т. д. Стекло для телефонов, автомобильное стекло, стекло для камер и т. д. ЖК-экран, стекло K9, резка фильтров, резка зеркал и т. д. |

| Ускорение | 1G |

| Применимые отрасли | Стеклянная промышленность: оптическое стекло, стекло K9 и сверхтонкое стекло. Бытовая промышленность: высокоборосиликатное стекло, кварцевое стекло, стекло для сантехники. Автомобильная промышленность: автомобильное стекло, лобовое стекло и т. д. Новая энергия: фотоэлектрическое стекло. Бытовая техника: стекло для бытовой техники, стекло для панельного освещения. Недвижимость: архитектурный декор, стекло для ванных комнат и т. д. |

| Требования к техническому обслуживанию | Рекомендуется оптическая юстировка каждые 200 часов и замена охлаждающей жидкости каждые 1000 часов. Доступна регулярная удаленная диагностика и обновления программного обеспечения. |

| Уровень шума | Рабочий уровень шума составляет 70 дБ, со встроенной системой шумоподавления, подходит для малошумной среды. |

| Мощность лазера | 30/50/60/75/80/90 Вт |

| Минимальный размер заусенца при резке | ≤5 мкм |

Применения:

Случаи и сценарии применения продукта для лазерной машины для резки стекла CKD:

- Лазерная машина для резки стекла CKD - это высокоточная лазерная режущая машина, подходящая для широкого спектра применений. Она идеально подходит для таких отраслей, как автомобилестроение, электроника и домашний декор.

- Эта небольшая лазерная машина для резки стекла идеально подходит для предприятий, которым требуется сложная и детальная резка стекла, например, для ювелиров, художников по стеклу и дизайнеров интерьеров.

- Лазерная машина для резки стекла CKD также является лазерной машиной для резки толстого стекла, что делает ее подходящей для резки толстых стеклянных заготовок для строительных и архитектурных проектов.

- Благодаря инфракрасному пикосекундному типу лазера эта машина обеспечивает точные и чистые разрезы на стеклянных материалах, обеспечивая высокое качество и эффективность производства.

- Уровень рабочего шума 70 дБ, а также встроенная система шумоподавления делают ее идеальной для использования в малошумной среде, где проблема загрязнения шумом является актуальной.

- Лазерная машина для резки стекла CKD работает при рабочем напряжении 220 В и лучше всего работает при температуре от 15°C до 30°C с относительной влажностью 20%-80%, что делает ее подходящей для чистых помещений или промышленных сред.

- Этот продукт сертифицирован по стандартам ISO CE, что обеспечивает соответствие стандартам качества и безопасности. Минимальный объем заказа составляет 1, а цена договорная в зависимости от конкретных требований заказчика.

- Детали упаковки включают деревянную вакуумную упаковку для безопасной транспортировки, а срок поставки составляет от 25 до 45 дней. Принимаются условия оплаты L/C и T/T, с возможностью поставки 60 комплектов в месяц.

- Частота импульсов раздельного лазерного источника лазерной машины для резки стекла CKD может регулироваться от 1 до 100 кГц, обеспечивая универсальность при резке различных толщин и материалов стекла.

Настройка:

Услуги по настройке продукта для лазерной машины для резки стекла для защиты окружающей среды (Модель: CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070C-50ECKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070S-80ECKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE, CKD-DP6070D-80ECKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070S-80TE, CKD-SP6070S-80ECKD-SP6070D-50E, CKD-SP6070D-60E, CKD-SP6070D-80TE, CKD-SP6070D-80ECKD-SP6070C-50E, CKD-SP6070C-60E, CKD-SP6070C-80TE, CKD-SP6070C-80E)

Торговая марка: CKD

Место происхождения: Китай

Сертификация: ISO CE

Минимальный объем заказа: 1

Цена: Договорная

Детали упаковки: Деревянная вакуумная упаковка

Срок поставки: 25-45 дней

Условия оплаты: L/C, T/T

Возможность поставки: 60 комплектов в месяц

Название продукта: Машина для резки и разделения стекла (все в одном)

Минимальный размер заусенца при резке: ≤5 мкм

Рабочая среда: 26℃

Условия окружающей среды: Лучше всего работает при температуре от 15°C до 30°C, с относительной влажностью 20%-80%, подходит для чистых помещений или промышленных сред

Метод охлаждения раздельного лазерного источника: Водяное охлаждение

Ключевые слова: Лазерная машина для резки стекла для защиты окружающей среды, машина для резки цветного стекла, волоконная лазерная режущая машина

Поддержка и услуги:

Наш продукт - лазерная машина для резки стекла - поставляется с комплексной технической поддержкой и услугами для обеспечения оптимальной производительности и удовлетворенности клиентов. Наша команда экспертов готова помочь с любыми вопросами, связанными с продуктом, устранением неполадок и потребностями в техническом обслуживании. Кроме того, мы предлагаем программы обучения, чтобы помочь пользователям максимально использовать возможности машины и эффективно достигать желаемых результатов. Вы можете положиться на наши специализированные службы поддержки, чтобы оперативно решать любые проблемы и обеспечивать бесперебойную работу ваших операций.

Упаковка и доставка:

Упаковка и доставка продукта:

Эта лазерная машина для резки стекла тщательно упакована для обеспечения безопасной доставки нашим клиентам. Она надежно упакована в деревянный ящик с пенопластовой подкладкой для предотвращения каких-либо повреждений во время транспортировки.

Наша специализированная команда по доставке позаботится о вашем заказе и обеспечит правильное запечатывание и маркировку посылки для точной доставки.

FAQ:

В: Какое название бренда лазерной машины для резки стекла?

О: Название бренда лазерной машины для резки стекла - CKD.

В: Какие сертификаты имеет лазерная машина для резки стекла?

О: Лазерная машина для резки стекла сертифицирована по стандартам ISO и CE.

В: Какие доступные модели для лазерной машины для резки стекла?

О: Доступные модели для лазерной машины для резки стекла: CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070C-50ECKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070S-80ECKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE, CKD-DP6070D-80ECKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070S-80TE, CKD-SP6070S-80ECKD-SP6070D-50E, CKD-SP6070D-60E, CKD-SP6070D-80TE, CKD-SP6070D-80ECKD-SP6070C-50E, CKD-SP6070C-60E, CKD-SP6070C-80TE, CKD-SP6070C-80E.

В: Каковы условия оплаты при покупке лазерной машины для резки стекла?

О: Условия оплаты при покупке лазерной машины для резки стекла: L/C и T/T.

В: Каковы детали упаковки лазерной машины для резки стекла?

О: Лазерная машина для резки стекла упакована в деревянную вакуумную упаковку.