50HZ 60HZ Working Frequency Laser Glass Cutting Machine with 1064nm Wavelength and Adjustable Cutting Speed from 0 to 500mm per Second

-

Площадь резки400 мм*500 мм/600*700 мм/600*900 мм

-

ИмяСтеклянная резка и расщепление

-

Система охлажденияВодяное охлаждение

-

Драйв двигательXy линейный двигатель + правитель решетки

-

Напряжение, мощность<8кВт, 220В переменного тока

-

МатериалСтекло

-

Расщепление лазерного источника мощности150 Вт (варианты: 250 Вт/350 Вт)

-

Точность резки±0,01 мм

-

Торговое названиеСтанок для лазерной резки стекла

-

Лазерный источник брендаРайкус

-

Точность±0,01 мм

-

Размеры машины1500 мм х 1200 мм х 1300 мм

-

Длина волны лазера1064 нм

-

Толщина стеклаМенее 25 мм

-

Ускорение1G

-

Система управленияКонтроллер с ЧПУ

-

Скорость резанияДо 3000 мм/мин

-

Размер машины1700мм*1700мм*1960мм

-

Будь ЧПУДа

-

Вырезать скорость0-500 мм/с

-

Точность резки±0,1 мм

-

Размер рабочего стола1300 мм х 2500 мм

-

Ширина импульса<10ps

-

Место происхожденияКитай

-

Фирменное наименованиеCKD

-

СертификацияISO CE

-

Model NumberCKD-DP6070C-50E CKD-DP6070C-60E CKD-DP6070C-80TE CKD-DP6070C-50ECKD-DP6070S-50E CKD-DP6070S-60E CKD-DP6070S-80TE CKD-DP6070S-80ECKD-DP6070D-50E CKD-DP6070D-60E CKD-DP6070D-80TE CKD-DP6070D-80ECKD-SP6070S-50E CKD-SP6070S-60E CKD-SP6070S-80TE CKD-SP6070S-80E

-

Minimum Order Quantity1

-

ЦенаNegotiated

-

Packaging DetailsWooden vacuum packaging

-

Delivery Time25-45 days

-

Payment TermsL/C, T/T

-

Supply Ability60sets per month

50HZ 60HZ Working Frequency Laser Glass Cutting Machine with 1064nm Wavelength and Adjustable Cutting Speed from 0 to 500mm per Second

Product Description:

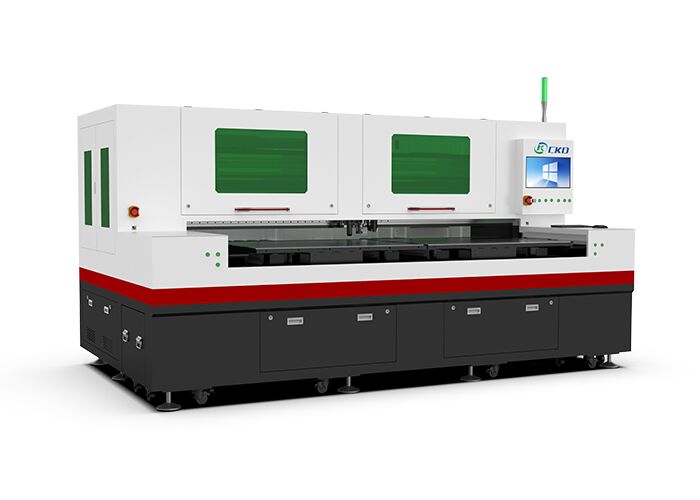

The Laser Glass Cutting Machine is a state-of-the-art solution designed to meet the diverse needs of the glass processing industry. As an advanced environmental protection glass laser cutting machine, it combines precision, efficiency, and durability to deliver outstanding performance for various glass cutting applications. Whether you are working with optical glass or thick glass, this machine offers unparalleled cutting accuracy and reliability, ensuring high-quality results every time.

One of the standout features of this laser glass cutting machine is its mobility. Equipped with heavy-duty wheels, the machine can be easily moved and repositioned within your workspace without compromising stability. The integrated locking mechanisms secure the machine firmly in place during operation, providing a stable working environment that enhances cutting precision and safety. This mobility feature is particularly beneficial in dynamic production settings where flexibility and space optimization are crucial.

In terms of size, the machine is available in two dimensions to accommodate various operational requirements: 2150mm × 2080mm × 1960mm and 2550mm × 2080mm × 1960mm. These dimensions ensure that the machine can fit comfortably into different workshop layouts while providing ample space for handling glass sheets of varying sizes. Despite its robust build, the machine’s design emphasizes compactness and space efficiency, making it suitable for both large-scale industrial facilities and smaller specialized workshops.

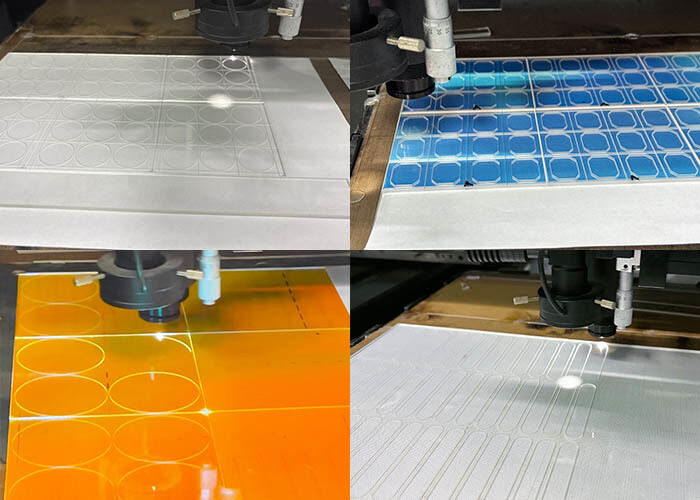

The Laser Glass Cutting Machine operates at a working frequency of 50HZ/60HZ, making it adaptable to different electrical standards worldwide. This flexibility allows for seamless integration into existing production lines without the need for extensive modifications. The machine’s core cutting technology is driven by an RFC02 (Radio Frequency CO2) laser source. This cutting-edge laser type is renowned for its high precision, energy efficiency, and ability to cut through various types of glass, including optical glass and thick glass, with minimal thermal distortion and exceptional edge quality.

Weighing in at 3500kg, this thick glass laser cutting machine boasts a sturdy and durable construction that ensures long-term stability and consistent performance. The substantial weight contributes to the machine’s vibration resistance, which is critical for maintaining cutting accuracy during high-speed operations. The robust build also supports heavy-duty usage, making it ideal for industrial environments where reliability and continuous operation are essential.

As an optical glass laser cutting machine, it is engineered to deliver smooth and precise cuts on delicate and high-value glass materials. The advanced laser technology minimizes material wastage and reduces post-processing requirements, thereby increasing overall productivity and cost-effectiveness. Additionally, the environmental protection glass laser cutting machine is designed with eco-friendly principles in mind, utilizing energy-efficient components and minimizing emissions, which aligns with modern sustainability goals.

In summary, this Laser Glass Cutting Machine is a versatile and high-performance tool tailored to the needs of glass manufacturers and processors. Its combination of mobility, precise laser technology, adaptable dimensions, and robust construction makes it an excellent investment for cutting optical and thick glass with precision and efficiency. Whether your priority is enhancing productivity, ensuring environmental sustainability, or achieving superior cutting quality, this machine stands out as a reliable and innovative solution in the field of glass laser cutting.

Features:

- Product Name: Laser Glass Cutting Machine

- Cutting Thickness: 0.03~25mm, suitable for various glass types

- Wavelength: 1064nm, ensuring precise and efficient cutting

- Noise Level: Operating noise level is 70dB with a built-in silencing system, ideal for low-noise environments

- Brand: CKD, known for quality and reliability

- Linear Speed: Up to 1000mm/s for fast and accurate cutting

- Advanced Fiber Laser Cutting Machine technology for enhanced performance

- Capable of thick glass laser cutting, handling thickness up to 25mm

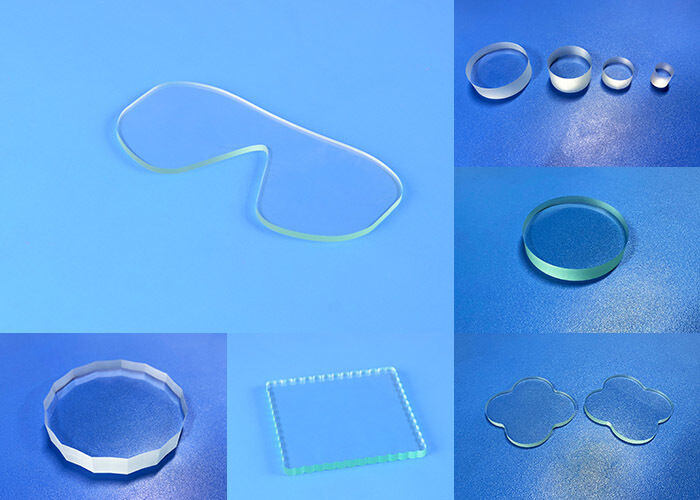

- Supports irregular glass cutting, providing flexibility for various shapes and designs

Technical Parameters:

| Support image and text formats | AI, PLT, DXF, BMP, Dst, DWg, LAS, DXP |

| Whether CNC | Yes |

| Wavelength | 1064nm |

| Splitting laser source Pulse Frequency | 1-100kHz |

| Cooling System | Water Cooling |

| Compatibility with Automation Systems | Supports integration with major automation systems, including robot interfaces and automatic loading/unloading systems. Standard industrial communication protocols (like Modbus, OPC) are supported. |

| Mobility | Equipped with heavy-duty wheels for easy movement and repositioning, with locking mechanisms for stability. |

| Linear guide brand | TPI |

| Cutting Accuracy | ±0.01mm |

| Transmission System | Rack and Pinion |

Applications:

The CKD brand Laser Glass Cutting Machine series, including models such as CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070D-50E, and CKD-SP6070S-80E, is designed to meet a wide range of glass processing needs in various industrial and commercial applications. Originating from China and certified with ISO and CE standards, these machines guarantee high reliability and precision cutting performance with a repeatability of ±1.5μm and an outstanding cutting precision of ±0.01mm. With a power consumption of less than 8KW and operating at AC220V, these laser glass cutting machines are energy-efficient and environmentally friendly, making them ideal for sustainable manufacturing.

The Environmental protection glass laser cutting machine variants in this series are perfect for industries that prioritize eco-friendly production processes. These machines utilize advanced laser technology to minimize waste and reduce harmful emissions, ensuring compliance with environmental regulations while maintaining high-quality cuts on various glass types. Their wooden vacuum packaging ensures safe delivery within 25-45 days, and with a supply ability of 60 sets per month, they are available to meet both small and large-scale production demands.

For businesses requiring precision on smaller scale projects, the Small glass laser cutting machine models in the CKD lineup provide compact, user-friendly solutions without compromising on cutting accuracy. These models are suitable for crafting intricate designs on glass used in decorative items, small electronic displays, and customized glassware. The integration of TPI linear guides and ultra-short pulse widths of less than 10ps ensures smooth and precise cutting operations, even on delicate glass surfaces.

When it comes to heavy-duty applications, the Thick glass laser cutting machine options within CKD’s product range are engineered to handle thick and tough glass sheets efficiently. These machines excel in industries such as automotive glass manufacturing, architectural glass processing, and solar panel production, where cutting thicker glass materials with minimal edge chipping and distortion is critical. The ability to negotiate pricing and flexible payment terms like L/C and T/T further enhances their accessibility for diverse industrial clients.

Overall, CKD’s Laser Glass Cutting Machine series caters to a broad array of application occasions and scenarios, including precision cutting for environmental protection glass, small-scale intricate glass designs, and robust cutting of thick glass materials. Whether in factories, workshops, or specialized manufacturing plants, these machines deliver exceptional performance, reliability, and versatility, making them indispensable tools for modern glass processing needs.

Customization:

CKD offers customized Laser Glass Cutting Machines tailored to meet your specific needs. Our product range includes models such as CKD-DP6070C-50E, CKD-DP6070C-60E, CKD-DP6070C-80TE, CKD-DP6070C-50ECKD-DP6070S-50E, CKD-DP6070S-60E, CKD-DP6070S-80TE, CKD-DP6070S-80ECKD-DP6070D-50E, CKD-DP6070D-60E, CKD-DP6070D-80TE, CKD-DP6070D-80ECKD-SP6070S-50E, CKD-SP6070S-60E, CKD-SP6070S-80TE, CKD-SP6070S-80ECKD-SP6070D-50E, CKD-SP6070D-60E, CKD-SP6070D-80TE, CKD-SP6070D-80ECKD-SP6070C-50E, CKD-SP6070C-60E, CKD-SP6070C-80TE, and CKD-SP6070C-80E, all made in China with ISO and CE certifications.

Our Single Table Glass Cutting Machine is designed to efficiently handle irregular glass cutting and polygonal glass cutting machine requirements, providing high precision with a pulse width of less than 10ps and a laser wavelength of 1064nm. The transmission system utilizes a reliable rack and pinion mechanism to ensure smooth and accurate motion. Operating at a working frequency of 50HZ/60HZ, these machines support various image and text formats including AI, PLT, DXF, BMP, Dst, DWg, LAS, and DXP.

We offer flexible customization services with a minimum order quantity of just 1 unit. Prices are negotiable to meet your budget and project scope. Each machine is carefully packaged using wooden vacuum packaging to ensure safe delivery. Our delivery time ranges from 25 to 45 days, supported by payment terms including L/C and T/T. With a monthly supply ability of 60 sets, CKD ensures timely fulfillment of your orders.

Support and Services:

Our Laser Glass Cutting Machine is designed to deliver precision and efficiency for all your glass processing needs. To ensure optimal performance, please follow the recommended maintenance procedures and operating guidelines outlined in the user manual.

If you encounter any issues during installation, operation, or maintenance, our technical support team is available to assist you with troubleshooting and resolving problems promptly.

We provide comprehensive services including installation support, operator training, routine maintenance, and software updates to keep your machine running smoothly.

For best results, always use the machine within the specified parameters and handle the glass materials as recommended. Regularly inspect the laser components and clean the machine to prevent dust accumulation and ensure accurate cutting.

Our commitment is to provide you with reliable support and quality service to maximize the productivity and lifespan of your Laser Glass Cutting Machine.

Packing and Shipping:

Product Packaging: The Laser Glass Cutting Machine is securely packaged using industrial-grade materials to ensure maximum protection during transit. Each unit is wrapped in anti-static foam and bubble wrap to prevent scratches and damage. The machine is then placed inside a sturdy wooden crate, which is reinforced with metal straps for added durability. Clear labeling and handling instructions are affixed to the packaging to guarantee careful handling throughout the shipping process.

Shipping: We offer worldwide shipping options for the Laser Glass Cutting Machine through reliable freight carriers. The machine can be shipped via sea freight, air freight, or express courier services depending on customer requirements and destination. Prior to shipping, all machines undergo thorough quality checks and testing. Tracking information will be provided once the shipment is dispatched to keep you updated on the delivery status. Custom clearance support and documentation are also available to ensure smooth import processes.